Why is the VDI Guideline 2035 important?

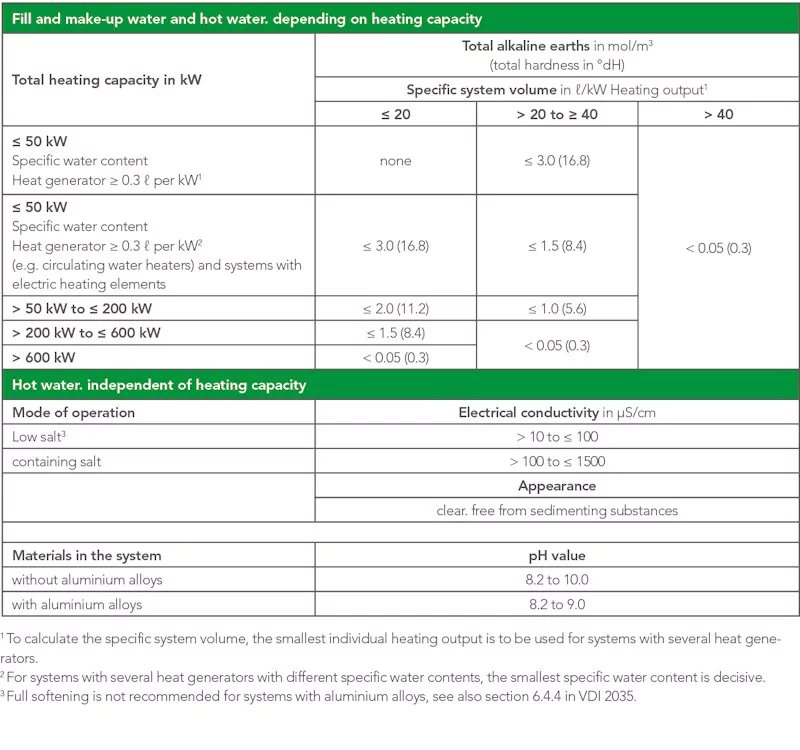

VDI guideline 2035 provides homeowners and specialist companies with clear guidelines for avoiding corrosion and limescale deposits in hot water heating systems. Inadequately treated heating water can cause considerable damage that impairs the efficiency of the system in the long term and increases operating costs. Hardness formers such as calcium and magnesium promote limescale formation, while dissolved oxygen can lead to corrosion. These factors have a negative effect on heating performance and increase energy consumption. VDI 2035 therefore defines specific limit values for water hardness, pH value and conductivity, which are to be achieved by softening and desalinating the water.

Of course, all the measures and values mentioned here apply almost identically to the ÖNORM H 5195-1 and SWKI BT 102-01 standards.

Areas of application for heating water treatment according to VDI 2035

➜ Systems with high water temperatures: At higher temperatures, the risk of stone formation increases, which is why water treatment to control the water hardness is particularly important here.

➜ Underfloor heating systems: The risk of deposits is high as the water circulates slowly and heat is stored for a long time, which can favour stone formation.

➜ New and existing systems: In both new and older systems, stone formation can lead to efficiency losses and damage if the water quality is not adjusted in accordance with the VDI 2035 guideline.

➜ DHW heaters and heat accumulators: These components are particularly susceptible to corrosion in the heating water circuit, which is why compliance with the directive is important to prevent corrosion.

➜ Mixed installations: In installations that combine different materials (such as aluminium and steel), pH value regulation is crucial to prevent corrosion damage.

➜ Installations with oxygen ingress: Installations with uncontrolled oxygen ingress (e.g. due to defective expansion vessels) require targeted water treatment to prevent corrosion caused by oxygen.

➜ Boilers with flue gas routing: Boilers in which the flue pipe material comes into contact with condensing flue gases are at risk of corrosion, especially with fuels containing sulphur or due to acidic condensates.

➜ Heat exchangers in condensing boilers: These heat exchangers are particularly susceptible to flue gas-side corrosion due to the low flue gas temperatures, which can lead to condensate formation and corrosive conditions.

Maintaining the ideal pH value

The pH value of the water should be in the optimum range to prevent corrosion:

Reduction of conductivity

Low conductivity prevents corrosion by restricting charge transport:

Checking the water hardness

The water hardness influences the formation of stones in the heating system. High temperatures increase the effect. VDI 2035 recommends

Minimisation of oxygen input

Excessive oxygen input promotes corrosion. VDI 2035 therefore recommends

Products for heating water treatment according to VDI 2035

Filtration: Removal of particles

The first step is filtration, in which coarse impurities such as rust and dirt particles are filtered out of the heating water. This is done with the help of fine filters, which remove harmful particles from the water.

Advantages:

➜ Reduced risk of deposits ➜ Protection against corrosion by removing foreign particles For filtration, UWS offers, for example, the MAGella dual filters twister5 & twister10, which effectively remove both magnetic and non-magnetic particles.

Desalination: Reduction of conductivity

Desalination of the water is another recommended measure. Desalination devices reduce the salt content in the heating water, which lowers conductivity and minimizes the risk of corrosion. This method is particularly suitable for systems without aluminum components.

Advantages:

➜ Reduced likelihood of corrosion ➜ Compliance with the manufacturer’s requirements for the heating water UWS offers, for example, the Heaty Profiline No. 2 a complete device for professional bypass treatment that enables efficient desalination.

Softening: reduction of water hardness

Softening the water removes calcium and magnesium ions, among other things, which are responsible for scale formation in the heating system. This measure prevents limescale deposits and improves heat transfer.

Softening protects against:

➜ Stone formation and limescale deposits ➜ Loss of performance in the heating system Especially in the event of recurring problems with the heating water, it is possible to install an all-round carefree package as a stationary system. The devices in the Racun series automatically soften, fill, treat and monitor the water quality.

pH value regulation: Optimum pH balance

VDI 2035 specifies an ideal pH value between 8.2 and 10.0 to prevent corrosion. If the pH value is too low, this can corrode the metal components of the system. Special mixed bed resins can be used to keep the pH value stable.

Advantages:

➜ Protection of the heating system against acid-induced corrosion ➜ Longer service life of the system components The Vadion pH-Control from UWS is a mixed-bed resin which, in addition to desalination, also automatically adjusts and stabilizes the pH value of the filling water within the required range and removes any residual hardness. We use our Vadion pH-Control in all our devices.

Use of additional devices

A make-up unit can be installed for automated treatment. These devices ensure that make-up water is treated automatically or manually as required and always complies with VDI specifications.

Advantages of make-up units:

➜ C ompliance with VDI 2035 and EN 1717 specifications ➜ Automatic adjustment of the water quality in the heating system The Heaty Complete PROfessional from UWS is a fully automatic IoT make-up unit including BA system separator for small heating and cooling systems that enables controlled make-up.

What must the heating water be like?

Heating water should be clear and free of sedimenting substances, with a pH value of 8.2 to 10.0 (8.2 to 9.0 for aluminum parts) and a conductivity of less than 100 µS/cm with low-salt operation.

When does heating water need to be desalinated?

Desalination is required if the water hardness or conductivity is above the limit values specified in VDI 2035, especially if a conductivity of less than 100 µS/cm is required.

How many microsiemens may heating water have?

The maximum conductivity should not exceed 100 microsiemens per centimetre (µS/cm) in order to minimize corrosion and optimize heating performance.