Heating water treatment and heat pumps – why water quality determines efficiency and service life

Heat pumps are one of the most sought-after heating technologies today—not only because they use renewable energy, but also because, with the right system design, they are particularly efficient and durable. However, while many people focus on how heat pumps work, one crucial aspect is often underestimated: heating water treatment.

Whether you have a heat pump for radiators, underfloor heating with a heat pump, or a combined system for hot water and heating, the water quality in the heating circuit has a significant impact on efficiency, service life, and reliability.

What is a heat pump and how does it work?

A heat pump is a heating system that raises environmental heat to a usable temperature level. Depending on the design, it extracts energy from either the outside air, the ground, or groundwater, where it is constantly available in almost unlimited quantities.

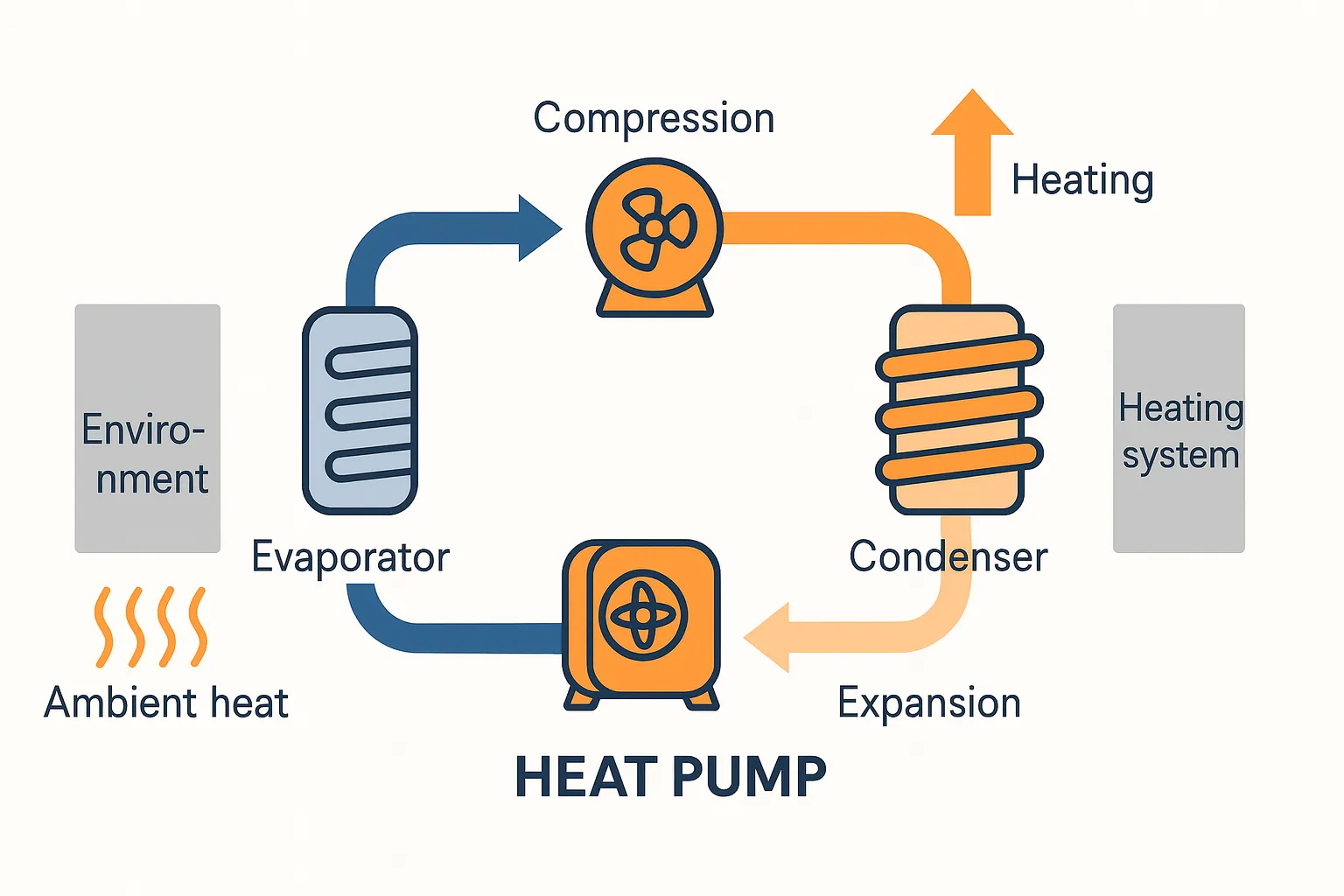

The heart of the system is the refrigerant circuit. It works in four steps:

- Evaporation – A special refrigerant absorbs heat from the environment at low temperatures and evaporates.

- Compression – An electrically powered compressor significantly increases the pressure and thus the temperature of the steam.

- Condensation – The heat, which is now at a higher temperature, is transferred to the heating water via a heat exchanger. This causes the refrigerant to liquefy again.

- Relaxation – Pressure and temperature drop via an expansion valve, and the cycle begins again.

The principle is similar to that of a refrigerator, except that the goal here is not to cool the interior, but to provide heat for the house.

The main types of heat pumps

- Air-water heat pump

Uses outside air as an energy source. Advantage: easy installation, no excavation work necessary. Ideal for renovations and new buildings. Efficiency may decrease at very low outside temperatures, which is why good system design is crucial. - Brine-water heat pump

Extracts heat from the ground via geothermal probes or surface collectors. Since ground temperatures remain relatively constant, efficiency remains very stable throughout the year. However, this type of construction requires drilling or earthworks, which may be subject to approval. - Water-water heat pump

Uses groundwater as a heat source. Since groundwater has relatively high temperatures throughout the year, this type of system is one of the most efficient. However, it requires a water permit and two wells (a supply well and a discharge well).

Efficiency and system dependency

The efficiency of a heat pump is often expressed as COP (coefficient of performance). A COP of 4, for example, means that around 4 kWh of heat is generated from 1 kWh of electricity. However, this value does not depend solely on the heat pump, but also on:

- the flow temperature of the heating system (low temperatures = higher efficiency),

- the design of the heating surfaces (e.g., underfloor heating or large radiators),

- and – often underestimated – the quality of the heating water.

Even the best heat pump loses efficiency when deposits or corrosion hinder heat exchange. Heating water treatment is therefore not a minor issue, but a key element for long-term, trouble-free operation.

Heating water as the key to efficiency

When it comes to heat pumps, many people first think of electricity consumption, heating curves, or insulation. Few consider pH value, conductivity, and water hardness—and this is precisely where one of the greatest levers for efficiency lies.

Treated heating water ensures that the circulating water does not cause corrosion, does not form deposits, and that heat transfer functions without hindrance.

The following applies in particular to heating water for heat pumps:

- pH value: too acidic or too alkaline can corrode metal parts.

- Conductivity: too high → risk of corrosion, too low → risk of static charge.

- Hardness: too much calcium reduces heat transfer, increases energy consumption, and puts strain on pumps.

Heaty Ferriline No. 2

Complete unit for professional bypass treatment, sludge and magnetite filtration in the hot water area incl. MAGella twisterTo the product

Why heating water particularly affects heat pumps

Compared to a gas or oil boiler, a heat pump operates at significantly lower flow temperatures, typically in the range of 30 to 55 °C. This makes it particularly efficient – but also more sensitive to problems in the heating circuit.

Even small deposits on the heat exchanger surfaces act as an insulating layer. At low flow temperatures, this effect is much more significant than with conventional heating systems: efficiency decreases, power consumption increases, and the heat pump has to run longer to reach the desired room temperature.

In addition, magnetite or sludge deposits can not only impede heat transfer, but also block circulation pumps or mechanically damage the heat exchanger. This is particularly critical in systems with underfloor heating or large system volumes, as the water quantities and pipe lengths increase the risk of deposits and corrosion products. Over the years, untreated heating water can thus become a real efficiency killer.

Heaty Profiline No. 2

Complete unit for professional bypass preparation, magnetite filtration and filtration incl. Hot water pumpTo the product

The role of VDI 2035 – and why manufacturers insist on it

The VDI 2035 guideline sets clear limits for conductivity, hardness, and pH value to prevent corrosion and scale formation in hot water heating systems. These values are not just technical recommendations—many heat pump manufacturers now explicitly require compliance with them as a prerequisite for warranty or guarantee claims.

This means that if, in the event of damage, it is proven that the heating water does not comply with the VDI 2035 specifications, the manufacturer can refuse to honor the warranty—even if the heat pump is still new.

Consequences for operators and specialist companies

Professional heating water treatment in accordance with VDI 2035 therefore not only protects against deposits and corrosion damage, but also against expensive warranty losses. It ensures optimal operation of the heat pump, maintains high efficiency, and can significantly extend the service life of the entire system.

💡 Practical tip:

- Analyze and document values regularly – ideally during commissioning, after initial filling, and after each refill.

- Record measurements at the customer’s premises in writing – this protects specialist companies in the event of a warranty claim.

- Only use treated water in accordance with VDI 2035 for refilling.

Heaty Complete Professional

The Heaty Complete PROfessional is the world’s first smart IoT top-up system incl. Cloud connection – fully automatic, leakage protection and digital water meter.To the product

Efficiency, costs, and service life—everything is connected

Whether a heat pump is “worth it” depends not only on electricity prices and subsidies. The heating system itself must also work optimally.

A few facts:

- Heat pump service life: Clean, corrosion-free heating water increases service life by up to 30%.

- Heat pump efficiency: Clean heating water can reduce electricity consumption by up to 15%.

- Heating costs Heat pump: Unnecessary repairs due to silted heat exchangers or defective pumps can quickly run into four-figure sums.

Conclusion

A heat pump can only work as well as the system in which it operates. Anyone interested in heat pumps should always keep an eye on the heating water.

Even the best technology loses its advantage if limescale, corrosion, and sludge clog the heat exchanger.

Consistent heating water treatment not only ensures efficiency, but also the cost-effectiveness and service life of the heat pump system.