Why is VDI Guideline 6044 important?

Especially in cooling water systems, there are new requirements due to complex system components and a variety of different materials. Mixed installations and contamination lead to operational disruptions, efficiency losses and repair work on cold and cooling water circuits, which in turn can lead to corrosion and deposits. This is often due to inadequate preparation and treatment of the filling, supplementary and circulating water as well as insufficient pressure maintenance and degassing. Therefore, VDI 6044 was published in April 2023 to proactively prevent damage in cold water and cooling circuits.

The guideline is based on BTGA rule 3.003 and applies to closed cold and cooling water circuits with a maximum circulating water temperature of < 40 °C and a total volume > 1,000 l (without buffer storage). Compared to the VDI guideline 2035, new values have been added to the VDI guideline 6044, such as for chloride, sulfate, and nitrate, as well as TOC, iron, zinc, copper, aluminum, and ammonium. The general total hardness requirement of < 8.4 °dH is broader than in the VDI guideline 2035 due to the lower operating temperature prevailing in larger systems. These specifications must be taken into account in planning, construction, and operation in order to prevent malfunctions or damage to the system.

VDI 6044 – the guideline for water quality in cooling systems

VDI 6044 is entitled “Prevention of damage in cold water and cooling circuits” and is the authoritative guideline when it comes to the planning, operation, and maintenance of cooling circuits, for example in data centers.

-

- High availability: Downtime is not an option – cooling must run 24/7/365.

- Constant conditions: Even the smallest deviations in temperature or water quality can have an impact.

- Large volumes: Cooling water systems in data centers often move thousands of liters – mistakes have correspondingly multiplied effects.

VDI 6044 therefore sets clear requirements for the cooling water and specifies how to avoid corrosion, deposits, and biological contamination.

VDI 6044 deals with, among other things:

Why water treatment is worthwhile:

Safety through water treatment with UWS technology

Efficient services and solutions for proper water treatment in cooling systems

Circulating water treatment using the bypass process

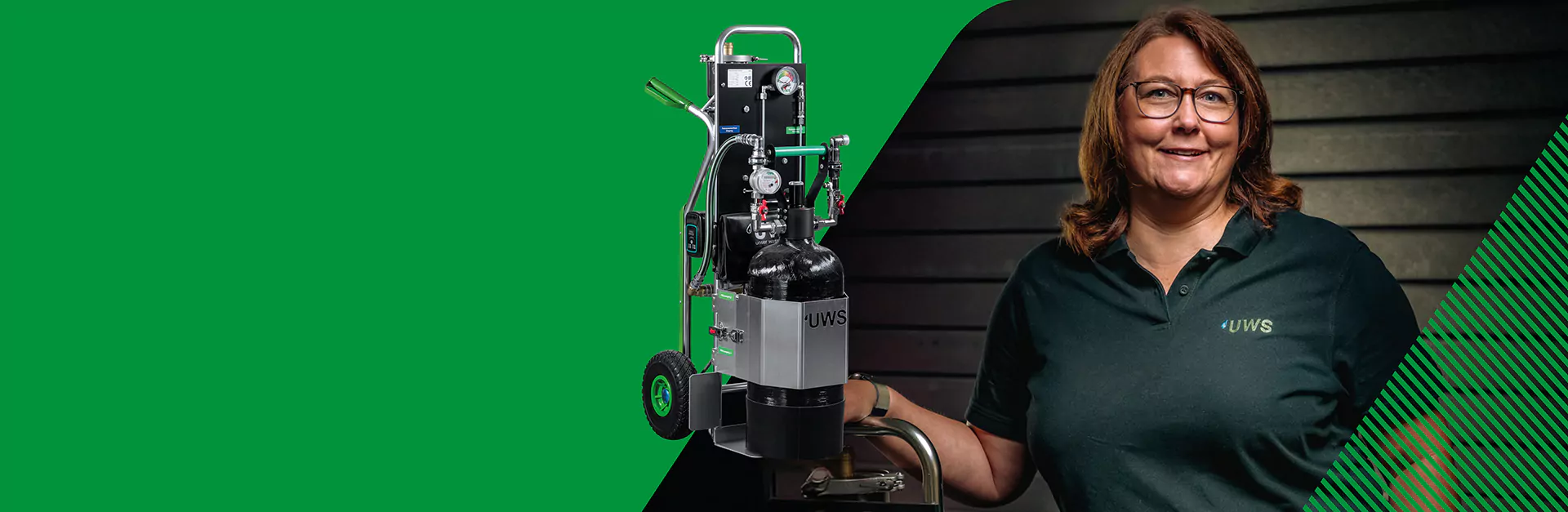

In order to ensure the water quality in closed systems according to VDI 6044, the circulating water must be continuously treated using the bypass process (side stream line). This enables the operator to reliably comply with the relevant specifications and prevent the system’s performance degradation due to corrosion. The treatment devices are suitable for both mobile and stationary use and can also be booked or rented as a service. Without interrupting operations, the cooling water can be treated to meet the requirements of VDI 6044. UWS devices from the Heaty Racun series for treatment and filling operate largely automatically and do not need to be supervised throughout the entire process. Of course, we also offer treatment devices for smaller systems, such as the Heaty Ferriline No. 2 and Heaty Profiline No. 2, make-up water devices from the Complete series, dual filters from the MAGella Twister series, and the MAGella Side Stream Filter.

Free VDI 6044 training

Our team will come to your premises and provide training on the most important aspects of VDI 6044.

We will also address questions relating to cooling and heating water treatment. We explain the technical possibilities and opportunities offered by water treatment.

Of course, we will bring samples of our Heaty Complete Home / Advanced / PROfessional make-up water systems, MAGella magnetite filters, and treatment devices such as Ferriline and Profiline.

Incidentally, our team is also an expert on Ö-NORM H 5195-5 (Austria) or SWKI BT 102-1 (Switzerland).

And best of all: this service is free of charge!

Fully demineralized water with mixed bed resin Vadion pH-Control

In order to comply with the recommended values according to VDI 6044, ÖNORM H 5195-1, and SWKI BT 102-01, we have developed our mixed bed resin Vadion pH-Control. It not only desalinates the water to below 100 µS/cm, but also ensures that the pH value of the fill water remains within the specified range. In addition, the bypass process enables reliable removal of residual hardness and dissolved salts in the cooling water during ongoing operation.

Clean cooling water starts with the right filtration

Before fine-tuning the cooling system, the water itself must be right. The first step on the way to permanently stable system values is therefore filtration. Dirt, rust particles, and other solids are reliably removed from the water—an important prerequisite for preventing deposits and corrosion damage in the long term.

Your advantages:

➜ Significantly lower risk of sludge formation and valve sticking

➜ Protection of sensitive components against particle damage and corrosion

Our MAGella dual filters twister5 & twister10 offer you a tried-and-tested solution: they remove both magnetic and non-magnetic particles – efficiently, with low maintenance, and perfect for use in modern heating systems.

Desalination – stable values for clean cooling water

Desalination of the water plays a crucial role in ensuring that cooling circuits remain efficient and corrosion-free in the long term. The targeted removal of dissolved salts reduces electrical conductivity – and thus significantly reduces the risk of electrochemical corrosion. This method is the key to long-term stable system operation, especially in systems without aluminum components.

Your advantages:

➜ Significantly lower corrosion tendency thanks to low conductivity

➜ Reliable compliance with manufacturer specifications for cooling water quality

With the Heaty Profiline No. 2 , UWS offers a professional complete device for bypass desalination that has proven itself in practice for years. This gives you an efficient and reliable solution for keeping your cooling water in the green zone at all times.