What influences corrosion in heating circuits?

Corrosion in heating circuits: Influencing factors, water quality and typical sources of error

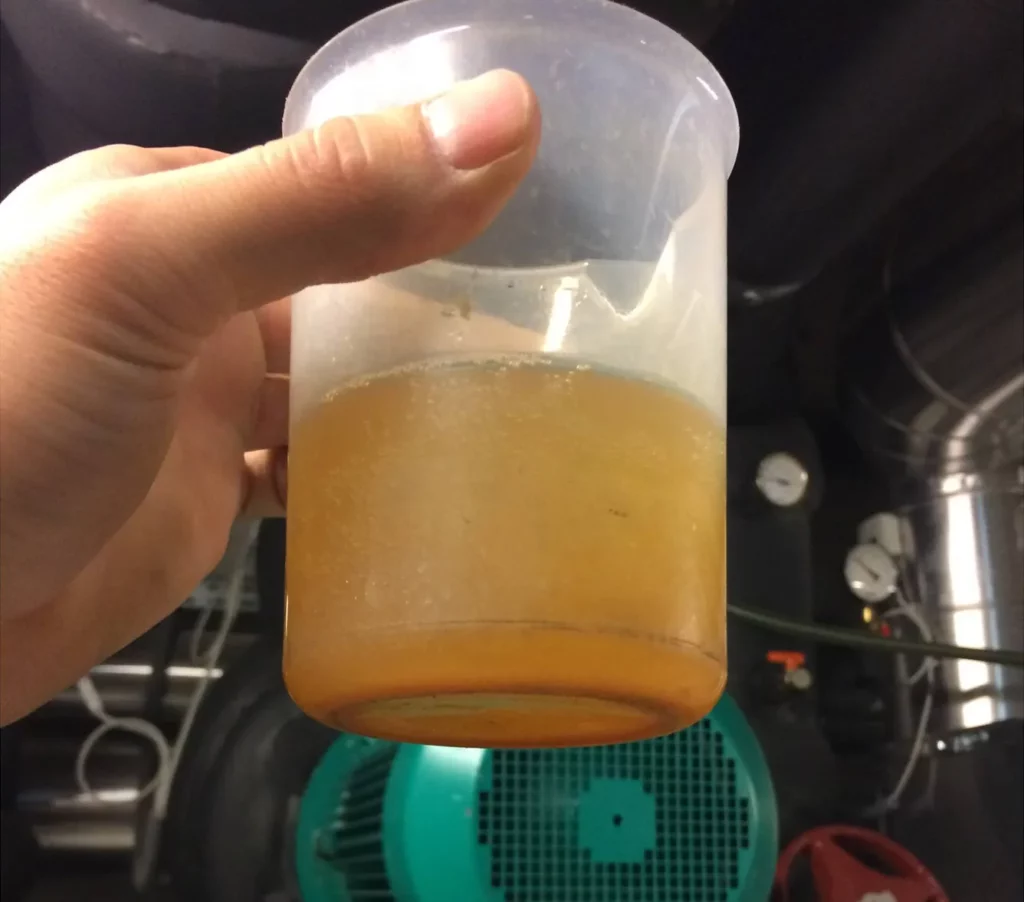

Perhaps this situation sounds familiar to you: A customer calls because the heating system is no longer working reliably. When you bleed the air, it quickly becomes clear what the problem is – the water has turned a rusty brown color. For any experienced heating engineer, this is an unmistakable sign that corrosion has taken place in the system over a long period of time.

In many cases, the causes are repeated: oxygen ingress, an unfavorable pH value, too high a salt concentration or a mix of several of these factors – often exacerbated by avoidable mistakes in practice. In this article, we take a closer look at the most common triggers for corrosion in the heating circuit and show you specific measures you can take to effectively prevent such damage.

Because one thing is certain: the quality of the heating water is crucial for the long-term value retention of any system. If it is neglected, there is a risk of rust formation, deposits and, in the worst case, costly breakdowns. If it is set and checked correctly, the heating system will run efficiently and trouble-free for years.

Oxygen: the invisible accelerator

Let’s start with one of the main drivers of corrosion: oxygen in the heating water. Even small amounts of dissolved air can cause considerable damage – especially in closed systems. The principle is simple: metal + water + oxygen = rust. And this process takes place just as reliably inside a heating system as it does outside on an iron fence.

The corrosion rate of many metals depends directly on the oxygen content in the water. If access is prevented, a protective passive layer can form – corrosion comes to a virtual standstill. However, if oxygen continuously enters the system, damage can be expected sooner or later.

How does oxygen get into the heating circuit?

Typical causes are

- Leaks that lead to regular refilling,

- Microbubbles in poorly vented systems,

- pipes that are open to diffusion (e.g. older underfloor heating systems without a barrier layer),

- Open expansion vessels, e.g. in the loft.

An example

An illustrative example shows how serious the impact can be: In an underfloor heating system without an oxygen barrier layer, the permanent oxygen ingress led to severe pitting within less than two years – even to a complete wall breakthrough in the boiler. The cause? An inconspicuous pipe with excessive diffusion, which ensured constant air ingress unnoticed.

What does this mean in practice?

The most important rule is: Keep the system as airtight as possible. These include:

- the use of closed diaphragm expansion vessels,

- Careful venting after filling,

- Regular checks for the smallest leaks.

If radiators regularly make noises, air constantly builds up or water needs to be topped up frequently, you should take note. In such cases, it is very likely that oxygen has entered the system over a long period of time – with corresponding consequences: Rust, magnetite sludge, clogged pumps or valves.

The good news is that once the system is sealed and vented, the condition often stabilizes significantly. Without oxygen, there is no corrosion – at least none worth mentioning.

pH value: Between acid and alkali

Another key factor for the stability of the heating water is the pH value – i.e. the chemical acidity of the water. If it is outside the ideal range, this can lead to massive damage, even in oxygen-poor systems. The decisive factor here is that both too low and too high pH values can corrode metals.

Two typical scenarios:

- Acid corrosion (pH < 6):

If the water is too acidic, hydrogen ions attack the metals directly. This produces hydrogen gas and dissolved metal ions – the metal is literally dissolved. Typical signs are the formation of bubbles (when venting) and noticeable discoloration in the heating water. - Alkali corrosion (pH > 8.5-9.0 for aluminum):

Water that is too alkaline can in turn corrode materials such as aluminum – e.g. in condensing heat exchangers or pump housings. The protective film on the aluminum becomes unstable and corrosion begins – here too without oxygen ingress.

How do such pH deviations occur?

- Refilling with demineralized water can cause the pH value to rise unintentionally (e.g. to > 10).

- Glycol or additive residues can degrade over time and form acids.

- Incorrect dosing of pH correctors or inhibitors can also significantly shift the value.

In extreme cases, heating water samples with pH values of around 4 are produced – visually recognizable by their cloudy, orange color, which is strongly reminiscent of multivitamin juice.

The reason: contact with air causes the previously dissolved iron to precipitate as an oxide. Such liquids are not only unappetizing, but also highly aggressive towards any metal component.

Recommendation: According to VDI 2035, the optimum pH value is between 8.2 and 9.0, especially for systems with aluminum components. In this range, stable passive layers can form on steel, copper or aluminum, which protect the metal from further attacks.

Our practical tip:

The pH value should be checked a few weeks after the initial filling at the latest. If it is too high or too low, targeted corrective measures, e.g. post-treatment with mixed bed resin or water changes, will help.

A simple solution is offered by our Vadion pH Control – the mixed bed resin reliably brings the pH value into the optimum range and at the same time reduces the conductivity of the water. More on this in the section: Conductivity and salt content: when water becomes an electrolyte

Check pH value and conductivity with the WaterBoy

Did you know that you can easily check both the pH value and the conductivity (we will go into this in more detail in the following section) of the water with our WaterBoy? This makes heating water analysis child’s play.

The app that comes with the WaterBoy guides you step by step through the measurement of the pH value and conductivity and simultaneously provides you with a measurement log as a pdf file.

Sounds interesting? Then take a closer look at the WaterBoy.

WaterBoy measuring case

The UWS WaterBoy measuring case contains everything the HVAC specialist needs to measure data in accordance with the VDI 2035, ÖNORM H 5195-1 and SWKI BT 102-01 standards in two L-BOXXES.To the product

Conductivity and salt content: when water becomes an electrolyte

(…and how Vadion pH Control plays the decisive role here)

Not all water is the same. This is because as soon as there are too many salts in the heating water – such as calcium, magnesium, chlorides or other ions – it changes its properties: it becomes conductive. And that is precisely the problem.

The higher the electrical conductivity, the easier it is for electrochemical processes to take place – in other words, corrosion currents between different metals are encouraged. The water then acts like a conductor of electricity, which additionally drives the corrosion.

An example from practice:

A heating system had been refilled with untreated tap water for years. The result: heavily calcified heat exchangers, clogged valves and rusted pipes. The analysis revealed that the conductivity was constantly above 300 µS/cm – far above the recommended limit value. The rusting process was running at full speed.

The solution: low-salt operation. According to VDI 2035, the conductivity of the heating water should ideally be below 100µS/cm – especially for sensitive materials such as aluminum. In this range, the water turns from a conductor of electricity into an insulator. Corrosion currents are inhibited and deposits are reduced.

Our treatment appliances and make-up stations – naturally with Vadion pH Control

Our Vadion pH Control mixed bed resin in our appliances helps you to bring the heating water into exactly this optimum range – without the need for complex chemicals or complex post-treatment.

What Vadion does:

- Desalination: It reliably reduces the conductivity to below 100 µS/cm – this corresponds to around 0-2 °dH.

- pH stabilization: At the same time, the pH value is adjusted to 8.2-10.0 (or 8.2-9.0 for aluminium).

- Application in the bypass: Vadion can also be used with filled systems during operation (3-80 °C) – ideal for retrofitting and renovation.

In practice, this means

- Rust protection due to low conductivity.

- Material protection due to optimum pH value.

- Less effort, more security.

No additional dosing, no risk of incorrect mixing – simply connect, let the water flow through and you’re done. Vadion is therefore one of the most efficient and safest methods of bringing heating water up to standard.

Mixed bed resin Vadion pH-Control

Our Vadion pH-Control is a mixed bed resin that not only desalinates the water to < 100 μS/cm (equivalent to 0-2 °fh) but also ensures that the pH value of the filling water is within the required range.To the product

Contamination, microbes and material mix: the underestimated risk factors

In addition to oxygen, pH value and salt content, there are other aspects that can promote corrosion – especially in existing systems or poorly prepared new systems. In everyday life, you encounter this more often than you might think.

1. variety of materials in the system

Steel, copper, brass, aluminum – many heating systems consist of a colorful mix of materials. And it is precisely this mix that can lead to galvanic corrosion in conductive water: The less noble metal (e.g. steel) becomes the anode and corrodes more quickly, while the more noble metal (e.g. copper) remains untouched.

This can lead to localized pitting, sludge deposits or even material failure. Particularly treacherous: copper ions can be deposited on steel and cause severe corrosion at certain points – a well-known phenomenon known as “copper corrosion on steel”.

The most important countermeasure: low-salt, standard-compliant water with the lowest possible conductivity. This reduces the electrochemical current flow – even in systems with mixed materials.

2. installation residues and dirt

Whether hemp, soldering flux, swarf or scale – residues inevitably get into the pipe system when installing a heating system. If these are not rinsed out thoroughly, they can react chemically or lead to rusting.

Therefore:

- Always rinse new systems thoroughly,

- For existing systems, carry out system cleaning before water treatment if necessary.

This prevents corrosion inhibitors from being blocked by deposits or new components from being damaged by contaminants.

3. microbiology in the boiler room?

Sounds strange – but it is not completely impossible. In certain systems (e.g. with long downtimes or very low temperatures), bacteria or biofilms can form. Some of these microorganisms reduce iron or sulphates and produce acids or gases such as hydrogen sulphide in the process – an ideal environment for corrosion processes.

Typical warning signs:

- slimy deposits in filters or separators,

- Noticeable odor when venting,

- cloudy, discolored heating water.

The solution: If suspected, carry out a microbiological analysis and treat with suitable biocides if necessary. Fortunately, this problem is rather rare – but if it occurs, it should be taken seriously.

Conclusion: Good heating water – long-lasting system

Corrosion is no coincidence. In almost all cases, it is the result of avoidable influences – usually air, salts or chemical imbalances in the heating water. The good news is that you can influence almost all of these factors yourself.

The most important levers are:

- Consistently avoid oxygen input,

- keep the pH value within the normal range,

- keep the conductivity as low as possible,

- degas, desalinate and rinse as required.

If you pay attention to these points, you will not only protect the system, but also your good reputation with the customer. After all, nobody is happy about rusty heat exchangers, clogged radiators or premature pump damage – regardless of whether it’s a new or existing building.

Our practical tip:

Treat the heating water like the heart of the system.

Would you cool your car with rainwater? Exactly. A modern heating system also needs optimized water that is matched to the materials, operating conditions and standards.

And if you can rely on simple, reliable helpers like Vadion pH Control or the WaterBoy you make your life as a specialist installer much easier – and ensure satisfied customers in the long term.