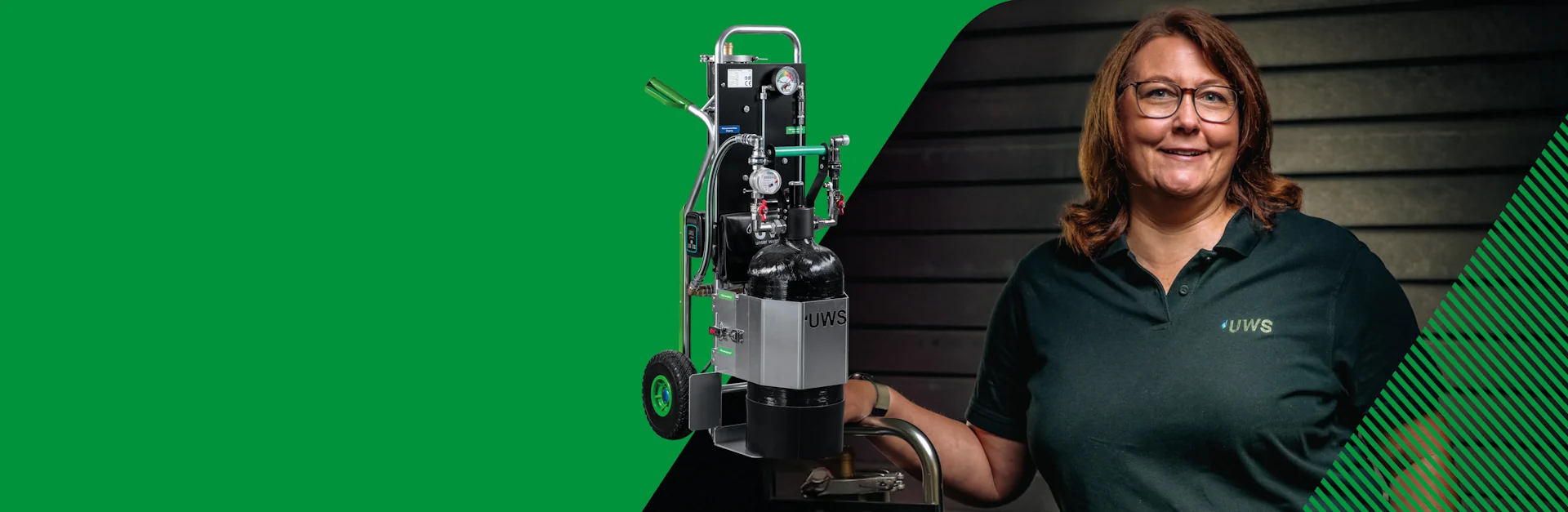

Our product range for bivalent heating water treatment

Our product range extends from the initial filling and replenishment of make-up water to magnetic flux filters and corrosion monitoring.

With UWS treatment units, they treat the heating water bivalently using the bypass process; the units soften, desalinate and filter at the same time.

Fully demineralized water with mixed bed resin Vadion pH-Control

In order to meet the values recommended in VDI 2035 (hardness of 0.3 °dH, conductivity ≤ 100 μS/cm and a pH value of 8.2 – 10.0 in stainless steel systems or 8.2 – 9.0 for aluminum components), we have developed our mixed bed resin Vadion pH-Control has been developed. In addition to desalinating the water to < 100 µS/ cm, it also ensures that the pH value of the filling water is within the required range. The application range is in a temperature range from 3 °C to 80 °C. This also makes it possible to remove existing residual hardness and dissolved salts in the heating water of a heating system during operation (bypass process)

Heating water treatment

Why

Heating water treatment?

Stone formation, corrosion and magnetite are frequent causes of damage in the event of problems with the heating system. The VDI 2035 specifies guide values for the heating water for these reasons. These form the basis of many warranty conditions – which planners, installers and operators should always keep in mind. If the specified guidelines are not adhered to, there is a risk of:

- Refusal of commissioning by the manufacturer

- Refusal of the warranty claim in the event of damage and

- Performance and efficiency losses

- Medium/long-term damage to the system.

A word about the most important standards

Core of the VDI 2035 is the prevention of stone formation and corrosion damage caused by water. EN 1717 regulates the protection of drinking water against non-drinking water and according to EN 14336, heating systems must be flushed before commissioning.

Other standards apply in other European countries. In Austria, for example, it is ÖNORM H 5195-1, in Switzerland SWKI BT 102-1, but many countries now base their standards on VDI 2035.

What values for heating water?

The values recommended by VDI 2035, ÖNORM H 5195-1 and SWKI BT 102-01 are a hardness of 0.3 °dH, conductivity ≤ 100 μS/cm and a pH value of 8.2 – 10.0 in stainless steel systems and 8.2 – 9.0 for aluminium components.

What must the heating water be like?

The heating water should be limescale-free, corrosion-free, clean and clear in accordance with the applicable standards. It should also not have an unpleasant odour.

When does heating water need to be demineralised?

If there are too many anions and cations in the water, it must be demineralised. Desalination removes several salts (cations and anions) from the water, which trigger corrosive and decomposing reactions in the heating system. In turn, desalination prevents scale formation, as calcium and magnesium are also removed. This reduces conductivity enormously as (almost) all cations and anions and therefore conductive salts are removed.

The advantages of low conductivity and therefore demineralisation:

– The lower the conductivity, the higher the heat capacity

– Higher tolerable oxygen concentration

– Significantly reduced likelihood of corrosion

– Specifications of all manufacturers are met

How many microsiemens may heating water have?

The standards differentiate between low-salt and high-salt operating modes. For low-salt heating water, a conductivity of > 10 to ≤ 100 µS/cm applies; high-salt heating water should be > 100 to ≤ 1,500 µS/cm.

The higher the conductivity in the water, the greater the likelihood of corrosion. The salts dissolved in the water largely determine the conductivity. A high salt content causes high conductivity. Oxygen binding agents and corrosion inhibitors also increase conductivity. Electrochemical corrosion only takes place if the installed materials come into contact with an electrically conductive medium. Conversely, this means that low conductivity reduces or slows down corrosion in the heating system.

How can heating water be treated?

In order to fulfil the values recommended in VDI 2035, there are special mixed bed resins (ion exchangers). The UWS Vadion pH-Control not only desalinates the water to < 100 µS/ cm (corresponds to 0-2 °dH), but also ensures that the pH value of the filling water is within the required range. The application range lies within a temperature range of 3 °C to 80 °C. This also enables the removal of existing residual hardness and dissolved salts in the heating water of a heating system during operation (bypass process). With our treatment devices, you fulfil all manufacturer specifications.